Continuing

Progress

A look inside the operations of the County’s landfills reveals environmental engineering and stewardship at the highest levels, reflected in a variety of activities: the design and location of each fill area, airspace preservation, prevention of hazardous waste from being buried, mitigation of naturally occurring impacts, and even in the heavy equipment we use.

Systemwide operations highlights

4,996,158 TONS

Buried Waste

762,966

Total Fee booth

transactions

552

Compost Applied for

Beneficial Reuse

13,768

GREENWASTE

repurposed for composting

88,500

of heavy equipment

Total operational hours35,546

Calls handled

at HQ reception

1,800

Habitat

plantings

1,697,947 TONS

Soil received

Soil received

513,649TONS

Asphalt

received

29,277

Matresses recovered

Saving Space

As important as it is for OCWR to report on the tonnage accepted and buried each year, it is equally important to count and measure the space in the landfills that did NOT get filled. We call this preserving airspace, and our pivot to resource recovery is already paying dividends.

The airspace preserved in 2021 is roughly equivalent to the space of almost four Olympic-sized swimming pools:

| MATTRESSES | SCRAP METAL | COMPOST |

| 805 tons | 1,597 tons | 13,451 tons |

Shifting to

renewable diesel

Progress toward efficiency in operations, resource recovery and environmental stewardship can be seen in OCWR’s fleet of heavy equipment. In July, we converted to using renewable diesel (RD) fuel.

OCWR operates 94 off-road heavy-duty vehicles (HDVs) powered by a total of 104 diesel engines. It is estimated that this fleet consumes approximately one million gallons of ultra-low sulfur diesel fuel per year. After successful completion of a pilot project to explore using RD in HDVs at Olinda Alpha Landfill, OCWR converted to using RD systemwide. The purpose of RD conversion is to seek to reduce fleet emissions of greenhouse gases and pollutants such as nitrogen oxide (NOx), fine particulate matter (PM10), and sulfur oxides (SOx).

The estimated results of RD conversion:

| Emission Type | Baseline | RD Emissions |

| NOx | 24.232 tons/year | 21.653 tons/year |

| PM10 | 1.077 tons/year | 0.765 tons/year |

| SOx | 0.1003 tons/year | 0.0028 tons/year |

| Reduction | Percent Reduction |

| 2.579 tons/year | 11% |

| 0.312 tons/year | 29% |

| 0.0975 tons/year | 97% |

| Emission Type | Baseline | RD Emissions | Reduction | Percent Reduction |

| NOx | 24.232 tons/year | 21.653 tons/year | 2.579 tons/year | 11% |

| PM10 | 1.077 tons/year | 0.765 tons/year | 0.312 tons/year | 29% |

| SOx | 0.1003 tons/year | 0.0028 tons/year | 0.0975 tons/year | 97% |

Working safely

Progress does not happen by accident, and high productivity is achieved only when work is conducted safely. The waste industry is among the top-10 high hazard industries, so safety is the thread that weaves together the fabric of our operations. Here are some highlights:

- Generated the lowest workers compensation claims it has seen over the last 12 years.

- Improved operational safety performance at all three landfills; ending the year with Total Recordable Injury Rates (TRIR) below 2019 industry standard rates.

- Reduced TRIR by effective supervision and employee engagement via safety tailgate meetings and training.

- OCWR supervision coached and mentored in the field; efforts were supported by a maturing Standard Operating Procedures program (SOP Playbook).

- OCWR staff logged a total of 4,394 training hours in the County’s Learning Management System.

Standard Operating Procedures (SOP) Program Stats

Playbook/SOPs are continually being added and modified

More than 25,000 unique

inspections/submissions completed digitally.

More than 25 new SOPs

were identified and added to the Playbook.

More than 50 SOPs were

enhanced with

pictures, videos and task specific training.

Simulator stats

Recovering

green energy

The ability to recover and put landfill gas to its best and highest use, reflects sustainability and a circular economy. Working with our energy partners, OCWR utilizes landfill gas to power generators, which in turn produced more than 410,000,000 kwh of electricity in 2021. This is enough energy to power almost 69,000 homes in Orange County.

AVERAGE ANNUAL TOTAL WATER USE:

60 million

gallons

Utilizing water wisely

Limiting domestic water consumption at landfills is a key component of environmental stewardship. Since 2014, OCWR has implemented a Water Conservation Plan to reduce the usage of domestic water by using alternative sources. Preferred alternative sources include reuse of landfill-generated liquids such as leachate, condensate, extracted groundwater, collected stormwater and reclaimed water. These efforts support the state’s water conservation goals in response to the ongoing drought. The primary uses of water at OC’s landfills are for dust control and for the composting operations. Repurposing available liquids is central to efficient water management. In 2021, OCWR significantly increased our use of reclaimed water, reducing the reliance on domestic water. OCWR plans to increase the usage of environmental water by constructing a landfill liquid treatment system at the Frank R. Bowerman Landfill.

| POTABLE | |

| 2020 | 24.9 MG | 46% |

| 2021 | 25.5 MG | 39% |

| ENVIRONMENTAL* | RECLAIMED |

| 5.8 MG | 11% | 22.9 | 43% |

| 4.2 MG | 6% | 36.2 MG | 55% |

| POTABLE | ENVIRONMENTAL* | RECLAIMED | |

| 2020 | 24.9 MG | 46% | 5.8 MG | 11% | 22.9 | 43% |

| 2021 | 25.5 MG | 39% | 4.2 MG | 6% | 36.2 MG | 55% |

* Environmental water includes groundwater and stormwater, and naturally occurring liquids (leachate and condensate).

Restoring Habitat Areas

Habitat restoration is a critical component of OCWR’s compliance and environmental stewardship efforts. The restorations improve natural streamflow, raise the water table and provide a quality habitat for wildlife. Efforts include removing invasive and non-native plant species.

We have approximately 485 acres of habitat restoration projects underway throughout Orange County, including two new projects which took root in 2021:

- Trabuco Creek Mitigation project, located in O’Neill Regional Park, encompasses about 51 acres of managed land within which we are actively installing native plants and sycamore trees and removing invasive Arundo, a bamboo-like plant naturally found in eastern Asia. The Arundo plant reproduces quickly and outcompetes native plant species for access to soil and water.

- Prima Onsite Drainage includes the creation of 25,215 feet of riparian drainages over approximately 1.93 acres that will be planted and seeded with native plant species.

- Sycamore trees (Platanus racemosa) – we’re planting 307 sycamores in Trabuco creek

- Increased available habitat for sensitive species including the endangered least bell’s vireo (Vireo bellii pusillus) and southwestern willow flycatcher (Empidonax traillii extimus)

- Western cottonwood trees (Populus fremontii)

- Seep monkey flower (Mimulus guttatus)

- Virgate sand aster (Corethrogyne filaginifolia) CA rose (Rosa californica)

- California rose

Keeping the hazards out

OCWR landfills do not accept hazardous waste of any kind. But occasionally hazardous household waste products, such as paint, batteries, various chemicals and e-waste make their way to the refuse area.

The waste inspection team is our front line to prevent hazardous waste from being accidentally buried. Team members look in potential hiding spots such as buckets and wastebaskets. It is not uncommon for inspectors to find such hazardous waste items such as latex paint, certain light bulbs, batteries, computers and televisions.

| PAINTS | FLUORESCENT LIGHTS |

| 15,430 gallons | 2,142 pounds |

| TELEVISIONS | BATTERIES | COMPUTERS |

| 10,096 pounds | 2,451 pounds | 7,743 pounds |

| PAINTS | FLUORESCENT LIGHTS | TELEVISIONS | BATTERIES | COMPUTERS |

| 15,430 gallons | 2,142 pounds | 10,096 pounds | 2,451 pounds | 7,743 pounds |

Innovating what’s next

Demonstration projects provide opportunities for innovation toward continuous improvement.

BOWERMAN

Usage of Thermal Oxidizer

To remediate following the Silverado Fire, we used a technology not commonly employed at landfills, and it contributed minimizing landfill gas migration, emissions, and odors.

Compost Screening Equipment

We rented various pieces of compost screening equipment to determine which would best meet the needs of Bee Canyon Greenery.

Compost Placement Placed

finished compost at various locations to test the durability and beneficial usage of the compost we produce.

PRIMA

New Tarping System Demonstration

The new tarp machine, Tarparmor, demonstrated three major safety upgrades over the existing equipment: better visibility due to a new camera system, increased clearance and system does not require ground crews.

- New compost/hydroseed combinations for erosion control

- The application of all three combinations of compost and hydroseed prevented major erosions during heavy December rains.

OLINDA

Renewable Fuels Project

This exploration compared renewable diesel to conventional diesel. We tested it on several types of heavy equipment over six months.

Outcomes include:

- No loss of performance

- Burns much cleaner than conventional diesel creating less emissions

- 100 percent renewable and sustainable resource, which reduces dependence on diminishing fossil fuel supplies.

Building and

improving

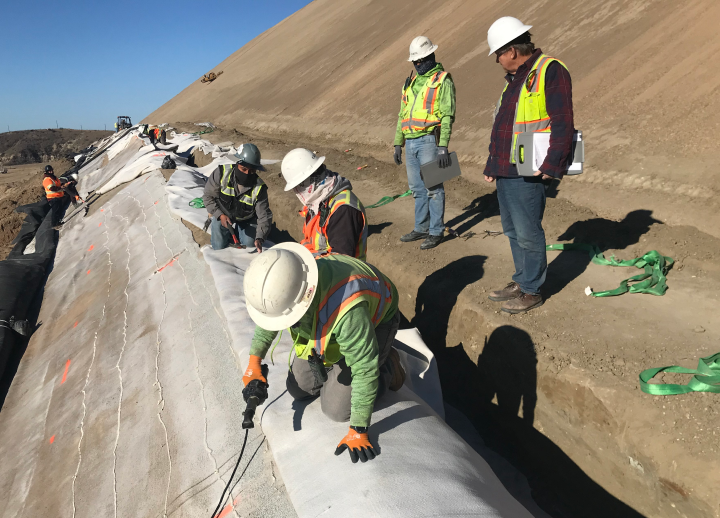

Landfills are living facilities, always changing to accommodate operational, environmental or legislative factors. Multi-million-dollar capital projects reflect this change and growth.

3 Capital projects

Completed in 2021 with a combined construction value of more than $12M that include the FRB Bee Canyon Greenery, FRB Silverado Fire Liner System Repairs and the FRB South East Perimeter Access Road Improvements.

30 Major projects

Completed in 2021 with a combined construction value of more than $8.8M that include channel diversions, cable rail fencing, erosion repairs, road repairs and resurfacing, stockpile relocation and repairs, and building improvements that include patio awnings, lighting and ice maker sheds.